Introduction

“Corporates are likely to invest USD 194 billion in building infrastructure for green hydrogen production in India over the next 10 years,” reads the recent headline of a leading national daily.

India has been at the forefront of building the green energy economy for the past few years. This industry has gained a lot of attention globally after the Government of India launched the National Hydrogen Mission on August 15th, 2021, aiming to make India a hub for green hydrogen production. With the successful launch of India’s green hydrogen mission and associated ecosystem, several of the nation’s largest organizations and international MNCs have pledged to collaborate via joint ventures, investments and setting up specialized factories for green hydrogen production in India. These investments are expected to help advance green hydrogen production in India and could be a big step in solving the sustainability and climate challenges facing Mother Earth.

So why this chase and why is Green Hydrogen seen as an exciting element to solve climate challenges of the world?

Let’s understand key properties of Hydrogen first –

- Hydrogen is the lightest and most abundantly available element and thus, is ideal for use in a wide range of industries.

- Hydrogen is a clean fuel as it yields water when combusted and hence doesn’t contribute to climate change.

So, what are key use cases of Hydrogen?

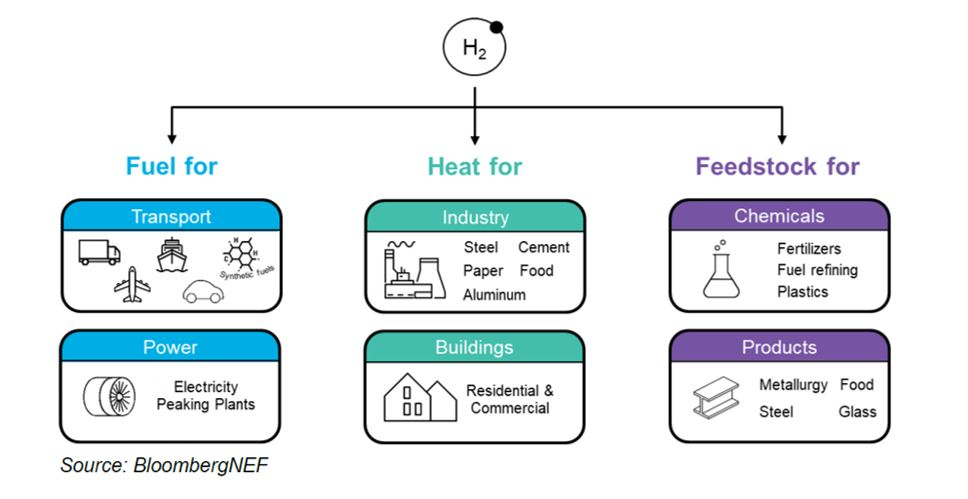

As the graphic above explains, Hydrogen can be used in a variety of use cases as a

- Fuel for

- Transport – Hydrogen is a light element (even in large amounts), and it can replace the traditional heavy weight electric batteries with lighter hydrogen fuel cells for all kinds of transportation requirements – cars, trucks, ships, and airplanes.

- Power –Electricity peaking plants typically use combustion turbines, also known as gas turbines, to generate electricity. These turbines burn fuel to drive a generator and produce electricity. Instead of using natural gas or other fossil fuels, hydrogen can be used as a clean fuel source to power these turbines.

- Heat source for

- Industry – Hydrogen is used as a heat source in a wide range of industries including steel, cement, paper, food, and aluminum where it helps in maintaining high temperatures or in the drying process during manufacturing. However, it’s worth noting that the adoption of hydrogen as a heat source may require infrastructure modifications and technological adaptations in existing industrial processes.

- Buildings – Hydrogen can be used as a heat source for space heating in residential, commercial, and institutional buildings.

- Feedstock for

- Chemicals & Products – Hydrogen is the key feedstock for several industrial processes and products. One of largest applications of hydrogen is in the production of ammonia (used in fertilizer and explosives, among other things), and in the production of methanol (used in adhesives and windshield wiper fluid). Hydrogen is also a vital ingredient in the decarbonization of steel, a carbon-intensive industry.

Now that we understand about Hydrogen and its versatile use cases, lets focus on Green Hydrogen.

Green Hydrogen – The Fuel of the Future!

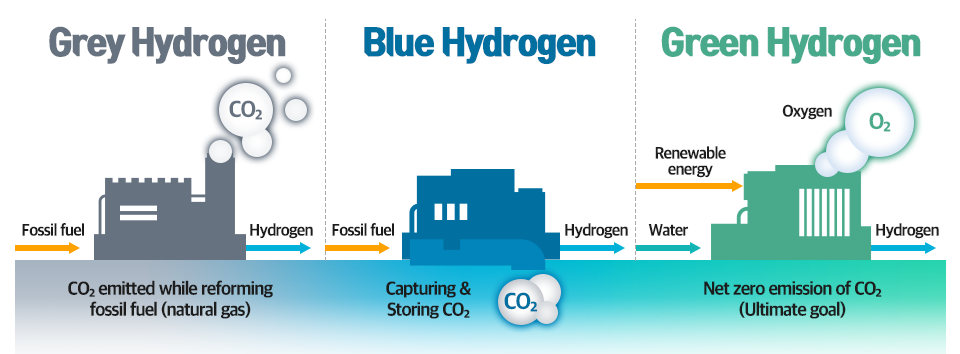

While Hydrogen is the most abundant available chemical element in the world, it is not found in its pure form in nature. It must be extracted from compounds such as natural gas, biomass, or water, through a process called electrolysis. Electrolysis requires electricity. The way the electricity is produced (using coal or renewable – solar or wind or Hydro), determines the type of hydrogen that is produced – Grey, Blue or Green Hydrogen.

Source: POSCO

Grey Hydrogen – Most of the hydrogen produced today is generated by using fossil fuels, particularly natural gas, through a process called steam methane reforming. The hydrogen generated by this method is called Grey Hydrogen. While this method is relatively cheap and efficient, it is not sustainable or environmentally friendly because it produces carbon dioxide as a byproduct and adds to the greenhouse challenge of our earth.

Blue Hydrogen – like Grey Hydrogen, blue hydrogen is also produced using fossil fuels, through a process called steam methane reforming but the Carbon Dioxide generated is captured and not released to the atmosphere.

Green Hydrogen – Hydrogen that is produced using renewable energy sources through the process of electrolysis is known as Green Hydrogen. In this process, hydrogen is separated from oxygen in water through an electric current (in an electrolyser). Renewable sources, such as solar or wind, are used to generated electricity required for electrolysis. Therefore, no greenhouse gases are emitted in this method of hydrogen production.

While production of green hydrogen is vital to decarbonizing Mother Earth, this process is currently not as cost-effective as compared to the production of grey or blue hydrogen. To close this “green premium,” the cost of renewable electricity and electrolysers would have to come down, and the cost of carbonization would have to increase.

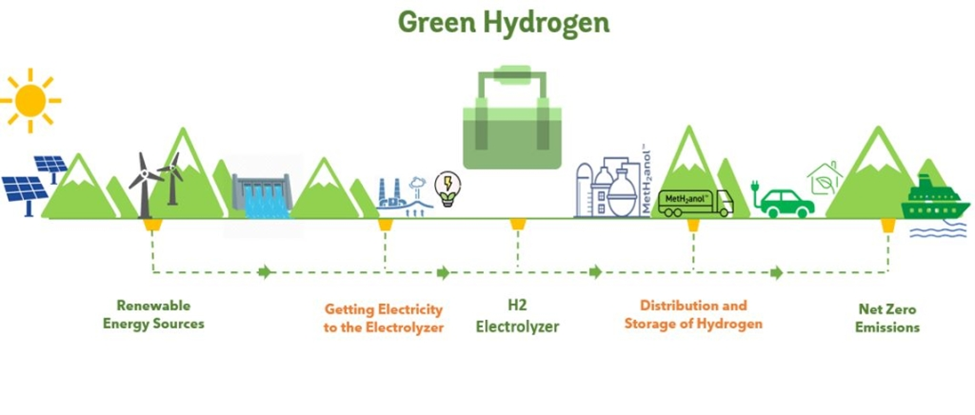

The Green Hydrogen Manufacturing ecosystem has three pivotal aspects –

Source: World Bank

- Renewable Energy Producers – setting up of renewable solar/wind power plants for generating electricity required for powering electrolysis reaction.

- Electrolysers Manufacturers – Infrastructure for manufacturing electrolysers, fuel cells, combustion systems, etc. – to enable the core electrolysis reaction.

- Distribution and Storage facilities for Hydrogen – Establishment of a strong Supply chain infrastructure – for transportation and delivery of hydrogen / ammonia. (Hydrogen converted to Ammonia makes it a much more effective fuel for transportation and distribution).

Future demand for hydrogen and specifically green hydrogen – Globally and in India

Given its versatile use cases, there is a growing demand for hydrogen as a replacement fuel for conventional fossil fuels such as coal and natural gas. According to the report by World Bank, dated June 2022, the global hydrogen demand reached 87 MT in 2020, and is expected to grow multifold to 500–680 MT by the year 2050. Infact between 2020 and 2021, the hydrogen production market was valued at $130 billion, and this is estimated to grow at a CAGR of 9.2% per year through to the year 2030.

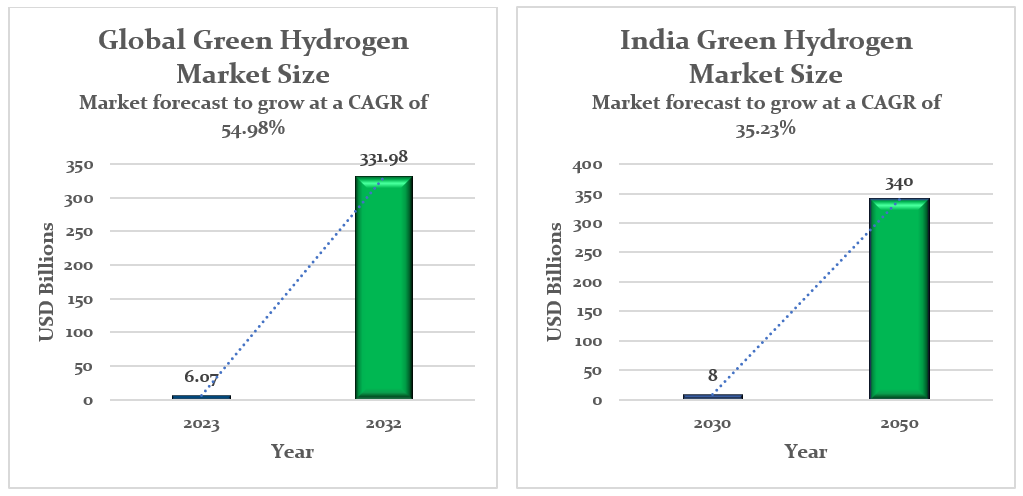

Given the increasing demand for hydrogen as a replacement fuel for fossil fuels, the global green hydrogen market size is expected to be around USD 6.07 billion in 2023 and this is expected to grow rapidly to become USD 331.98 billion by 2032, growing at a CAGR of 54.98% during this period.

Closer home, the cumulative market for green hydrogen production is projected to be USD 8 billion by 2030 and USD 340 billion by 2050.

Green Hydrogen Investments in India

Currently we are noticing investments in two large industrial ecosystems.

- Renewable Power Production

- Electrolyser Manufacturing

Significant investment announcements by large Indian companies

- The Adani Group has partnered with France’s Total Energies to create a green hydrogen ecosystem and has announced plans of investing USD 50 billion over the next 10 years.

- Reliance Industries has announced plans to invest USD 100 Billion over the next few years to set up a new clean energy business.

- ReNew Power has recently signed a preliminary agreement with the Egyptian government to invest USD 8 billion to produce green hydrogen in the country.

- ACME will invest USD 6.3 billion in Karnataka and Tamil Nadu for green hydrogen production.

- Sajjan Jindal led JSW Group has entered a collaboration with Australia-based Fortescue Future Industries and plans to invest INR 10000 crores on potential green hydrogen production in India.

- Avaada Group, a green energy firm raises $1-bn from Brookfield Asset Management for manufacturing of green hydrogen and solar modules.

Emergence of JVs for the Electrolyser technology partnerships

- Belgium’s John Cockerill in partnership with India’s Greenko, and Nevada-based Ohmium is setting up 2GW factories for manufacturing electrolysers in India to make the lowest cost green hydrogen in the country for industrial users.

- Ohmium is expanding its existing 500MW electrolyser plant in Bangalore, for which it recently secured USD 45 million in private funding.

- Reliance in partnership with Danish engineering firm Stiesdal is setting up four 1GW electrolyser factories by 2025.

- India’s Larsen and Toubro is in partnership with Norwegian electrolyser manufacturer Hydrogen Pro to set up manufacturing facilities.

- Indian fuel-cell manufacturer H2e Power plans to make solid-oxide electrolysers as well as setting up a 200MW factory to make anion exchange membrane (AEM) electrolysers.

Challenges & Way Forward for this industry

While opportunities for green hydrogen usage and production are very exciting, for this industrial ecosystem to continue to grow, we see the following challenges that will need to be surmounted:

- Create commercial demand and establish the role for green hydrogen in long-term energy strategies – The government’s push for creating demand for green hydrogen in end user segments like steel, fertilizer, refineries etc. will become extremely important to establish a pipeline for its supply and for the giving confidence to manufacturers to continue to make investments to set up the required manufacturing infrastructure.

- Evolving technology and continued investment in R&D – Many of the technologies used for green hydrogen manufacturing today are at a proof-of-concept stage and technology will continue to evolve. Hence investments in R&D will need to be robust and overall directed towards better production efficiencies and the reduced cost of manufacturing.

- Continued incentivization from the government to manufacturing companies to stimulate and encourage investments.

The push from the Government of India

As a sign of confidence, the Government of India (GoI) is also talking of implementing a Production linked Incentive (PLI) scheme for this industry and this is a big step in the right direction. In January 2023, the (GoI) gave the green signal to a USD 2.11 billion incentive plan to promote green hydrogen production. It is intended to help the industry attract an investment of up USD 125 billion to create the green hydrogen value chain. The incentives will help reduce the cost of green hydrogen, which is between Rs 320 and Rs 330 currently to between Rs 160 and Rs 170 per kilo by 2030. This will bring in on par with grey hydrogen and other fossil fuels.

Impact on Talent and critical jobs that will be in demand as this Industry grows multifold.

As this energy transition takes place in the coming decade, it will create many new job opportunities in several fields. The obvious choice of talent for corporates to go after will be clean tech and renewable energy professionals who bring the closest experience of having operated in a green energy ecosystem. The EV and Battery industry will also provide plausibility of talent in the areas of fuel cell, material sciences and storage technologies.

Few of the emerging jobs in the green hydrogen economy will be –

Design Engineers, Material Sciences Experts, Chemical Process Engineers

- Design Engineers: These professionals will design, build, and maintain the hydrogen production facilities that will be necessary to supply the increasing demand for green hydrogen.

- Material Sciences Experts: Will bring in expertise of material sciences to determine the purity of hydrogen and knowledge of other elements and compounds.

- Chemical Process Engineers: Provide knowledge of chemical processes, catalysts etc. and help in innovating.

Renewable Energy Specialists & Hydrogen Fuel Cell Technicians

- Renewable Energy Specialists: As the green hydrogen economy relies on renewable sources of energy to produce hydrogen, there will be an increased demand for professionals who can design, install, and maintain renewable energy systems, such as wind turbines and solar panels.

- Hydrogen Fuel Cell Technicians: Fuel cells are devices that convert hydrogen into electricity. Technicians will be needed to install, maintain, and repair these systems in various applications, such as cars, buses, and buildings.

Hydrogen Storage Specialists & Hydrogen Transportation Experts

- Hydrogen Storage Specialists: Hydrogen storage is a critical part of the green hydrogen economy. These professionals will work on developing safe and efficient storage methods for hydrogen.

- Hydrogen Transportation Experts: With the growth of hydrogen fuel cell vehicles, there will be a need for experts in transportation planning and infrastructure development to ensure the safe and efficient transport of hydrogen.

Environmental and Sustainability Experts:

- With the increasing focus on reducing carbon emissions and transitioning to a more sustainable energy system, there will be a growing need for professionals who can advise companies and governments on sustainable practices and policies.

Conclusion

As per the International Renewable Energy Agency (IRENA), hydrogen as a fuel will make up 12 percent of the total energy mix by the year 2050. It is further suggested that around 66 percent of the hydrogen demand by 2050 will be green in nature. Today, however, green hydrogen production makes up less than 1 percent of hydrogen required.

It’s clear that green hydrogen will play a pivotal role in the world’s transition to a sustainable energy future.

With policies in place, the world in consensus and leading large and small corporates backing it; Green Hydrogen will be the New Gold of the future!

About the Author

Vidya is a seasoned executive search consultant with more than a decade of experience in the Executive Search industry. She has successfully consulted and executed leadership and senior-level assignments for various large global MNCs and Indian corporate houses; and has a strong interest in the energy transition industry. She completed her MBA from Kirloskar Institute of Advanced Management Studies in 2012 and has been an integral part of WalkWater Talent Advisors since then.

About WalkWater Talent Advisors

Started in 2011, WalkWater is a boutique executive search and talent advisory firm. WalkWater focusses on leadership hiring across the CEO, CXO and CXO minus 1 level. Today the firm is one of the fastest growing Executive Search firms in India. In the last 12 years, we have worked across sectors with 350+ clients where we have closed 700+ senior management searches and completed 40+ bespoke talent advisory engagements. Over the years, we have emerged as a clear alternative to the global search firms and an equal in terms of industry expertise, client partnering, candidate connect and access. Our work has spanned large MNC and Indian Business houses and a whole array of start-ups / emerging companies across sectors.

By Vidya Venkataramani,

Senior Consultant,

Walkwater Talent Advisors